Aluminum in Architecture: ECOMS HOUSE Case Study & Key Benefits

As an experienced architectural designer, I will analyze a classic example of an aluminum structure building from Japan and explain the significant advantages of using aluminum in construction.

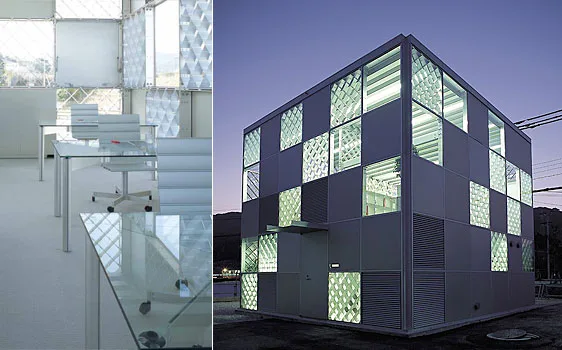

Case Study: ECOMS HOUSE, Japan

The ECOMS HOUSE is a seminal experimental residential project in Japan that showcases the potential of aluminum structures for industrial, lightweight, and rapid construction.

- Project Overview: The ECOMS HOUSE is located in Tosu City, Saga Prefecture, Japan. It functions as a residence combined with a SOHO (Small Office/Home Office). The building features a total floor area of approximately 106.58 square meters across two stories, built on a complete aluminum alloy structural system.

- Core Innovation & Reason for Choosing Aluminum: The project’s primary innovation is its full aluminum alloy structural system. It was commissioned by a manufacturer specializing in precision aluminum frames, aiming to explore new structural expressions unachievable with steel.

The design proposed a system where 1,200mm square panels were manufactured in a factory and then assembled on-site using only bolts. This prefabricated approach drastically reduces construction time, labor costs, and on-site waste.

The goal was to achieve a unique architectural aesthetic and spatial quality, leveraging aluminum’s properties to create intricate structural nodes and a lightweight building form.

able: Reasons for Using Aluminum in the ECOMS HOUSE Project

| Reason for Material Choice | Manifestation in the Project | Direct Value Created |

|---|---|---|

| Pushing Technical Boundaries | Exploring new structural expressions (e.g., structural walls from profiles) | Unique architectural aesthetics and spatial effects |

| High Prefabrication Level | Factory-made standard panels, bolt-on-site assembly | Fast construction, less on-site disruption and pollution |

| Leveraging Material Properties | Utilizing aluminum’s light weight, strength, and workability | Enabled delicate structural joints and a light building form |

| Corporate Technology Showcase | Served as a demonstration project for the client’s material |

Key Benefits of Aluminum Structures in Architecture

Based on the ECOMS HOUSE case and architectural theory, the advantages of aluminum structures are summarized below.

1. Lightweight yet High-Strength

Aluminum has a density of about 2.70 g/cm³, only one-third that of steel. This “lightweight high-strength” property offers major benefits:

- Reduced Structural Load: Ideal for sites with poor soil conditions, building additions, or long-span structures (like stadiums, greenhouses), minimizing foundation work.

- Easier Transportation & Installation: Lighter components simplify logistics and reduce costs, beneficial for sites with limited access.

- Superior Seismic Performance: A lighter building mass results in smaller horizontal inertia forces during an earthquake, enhancing safety.

2. Excellent Corrosion Resistance & Low Maintenance

When exposed to air, aluminum forms a protective oxide layer, giving it exceptional corrosion resistance. This means:

- Long Lifespan with Minimal Upkeep: Especially in coastal, humid, or industrial areas, aluminum structures require little to no protective maintenance, unlike steel, leading to lower lifetime costs.

- Long-Lasting Aesthetics: The material maintains its appearance over time, perfect for architecturally exposed structures.

3. High Recyclability & Sustainability

Aluminum is a highly sustainable building material.

- High Recyclability: It can be recycled repeatedly without loss of quality. The recycling process uses only about 5% of the energy required for primary production.

- Circular Economy: Supports green building certifications (like LEED) and reduces the environmental footprint of construction.

4. Design Flexibility & Fabrication Precision

Aluminum’s malleability allows it to be extruded into almost any shape. This enables:

- Complex Geometries: Facilitates the creation of dynamic curves and complex forms (e.g., Frank Gehry’s buildings).

- Integrated Functionality: Profiles can be designed to combine structure, drainage, and sealing in one element.

- High Precision: Compatible with Digital Design (BIM), allowing for accurate prefabrication and quality control.

5. Fast and Efficient Construction

The prefabricated nature of aluminum structures enables rapid assembly.

- Dry Construction: On-site work primarily involves bolting components, leading to faster project completion (up to 50% time savings).

- Quality Assurance: Factory-controlled manufacturing ensures consistent quality.

- Cleaner Sites: Reduces noise, dust, and waste, aligning with green construction principles.

Conclusion

The ECOMS HOUSE case study demonstrates that aluminum structures are an excellent choice for projects requiring speed of construction, unique aesthetic expression, resilience in harsh environments, and high sustainability goals. As a modern building material, aluminum offers a powerful combination of strength, durability, and design freedom, making it a compelling option for forward-thinking architects and builders.